| ← |

Plane carcasses Cylindrical, trapezoidal, multifaceted reinforcement frames for columns

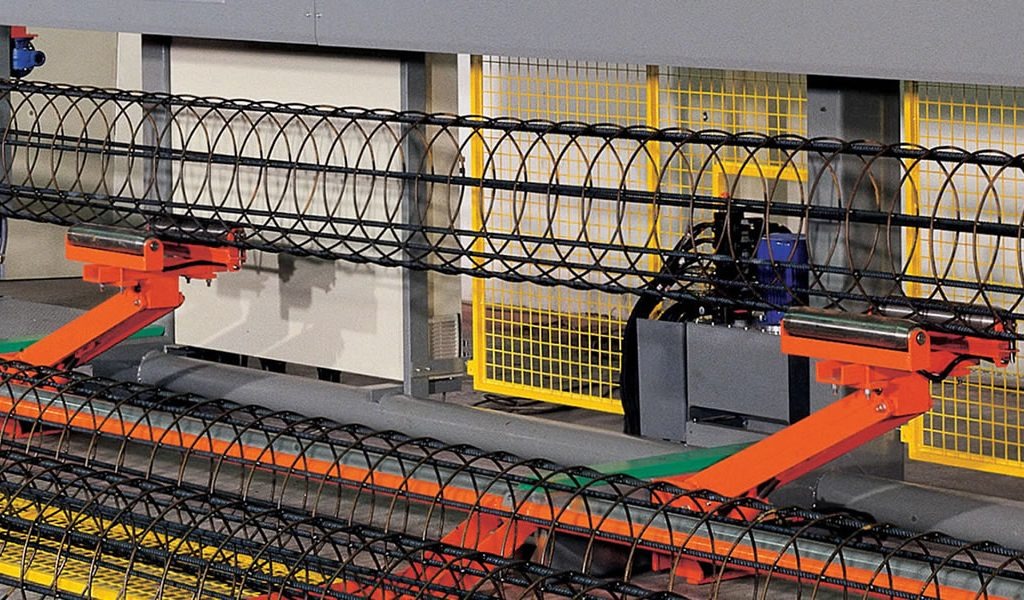

ARMABALT company, in order to meet the ever-growing demands of building reinforcement production in Baltic countries, purchased in 2017 high productivity machines CM PRO 1100 XP for reinforcement carcasses manufacturing.

CM PRO 1100 XP machines with modern software for cylindrical, trapezoidal, multifaceted form frames for columns, piles. Reinforcement bars which are cut of necessary length are connected by spiral method (serpentine) and were wrapping with reinforcing steel bar, various distance - established step of program.

Innovative constructive machines achieve a high productivity, high strength products, reinforcement bars semi-automatic welding according to the precisely accounted characteristics, which are for to the specific reinforcing steel brand.

Changing spiral step, which is based on precisely account according to used reinforcing steel characteristics, allows to produce building reinforcement products which compliant the highest technical requirements.

Machines produce carcasses for support columns, piles

In ARMABALT production are used CM PRO 1100 XP machines, which are controlled by software with servo engines sets, new mono blocks construction an other main news ensure flexible production conditions in a safe environment in production, allows clients to produce innovative and high-precision reinforcement products.

Technical data

| Features / Value | |

|---|---|

| Minimum diameter of carcass | 200 mm (8″) |

| Maximum diameter of carcass | 1100 mm (43″) |

| Maximum weight of carcass | 3 t (6600 lb) |

| Maximum length of carcass | 16 m (52′) |

| Maximum diameter bars | 6÷16 mm (#3÷#5) |

| Spiral step | 0÷500 mm (20″) |

| Longitudinal diameter bars | 12÷32 mm (#3÷#10 |

Reinforcing carcass parameters can be easily changed depending on each individual case in the customer order with a product specification. According to customers' drawings we produce various productions for concrete reinforcement.

| ↑ | ← |